Search This Supplers Products:aluminum lighting partslighting housinghest sinkglare shieldaluminum profileluminaire components

-

Types of stage lighting effects

1, spotlight

Spotlights are one of the most widely used stage lighting equipment. Currently, the market has 1KW, 2KW, and the most widely used is 2KW. It is mainly used for facial light, ear lighting, side sweeping, etc.time2019/08/22

-

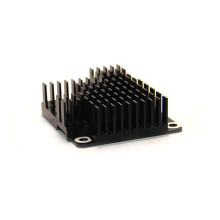

The main function of the LED heat sink is to continuously derive and dissipate the heat generated by the operation of the LED chip to the environment, so that the temperature of the chip is kept within the required range, thereby ensuring that the LED lamp can work normally.

time2019/08/29

-

The thermal resistance of the LED heat sink should include both thermal resistance and thermal resistance. For a certain shape of LED heat sink, the thermal conductivity is mainly related to the thermal conductivity of the heat sink material.

time2019/08/30

-

Lighting illuminates the architectural characteristics of the house and adds beauty to the house, curbing attractiveness and security.

time2020/03/19

-

The soffit lighting can be direct or indirect. Direct lighting refers to the light focused on a certain area or object...

time2020/04/16

-

Outdoor soffit lighting can be used to enhance architectural features at night or by illuminating dark areas, thereby reducing the likelihood of visitors tripping.

time2020/04/17

-

By marking public roads and sidewalks in many communities, street lights help keep streets safe and prevent drivers and pedestrians from having an accident.

time2020/05/16

-

The calculation of the lighting load depends on an equation: Watt = Volt x Ampere. Mathematically written as W = VA.

time2020/05/29

-

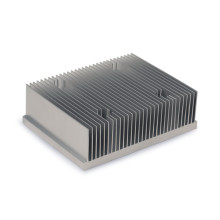

Heatsinks can be manufactured in a variety of ways depending on the required performance, cost and volume.

time2021/05/15

-

Heat sink material is the basis of performance, design is the essence of the product, and ultimately whether to achieve excellent design ideas, or how to achieve the results, what kind of products customers can finally get, all depend on the use of heat sink manufacturing technology.

time2021/05/22

-

Led heat sinks guarantee high light output and prolong the service life of high-performance leds

time2021/05/27

-

In order to explain how an LED works we must explain the four main components of an LED lamp; the LED Chip, the Driver, the The LED chip emits lights the in the bulb. Heat Sink, and the Optic lens.

time2021/06/07

-

Machined Springs are similar in function to Wire Wound Springs, but they are manufactured in a different way.

time2021/06/09

-

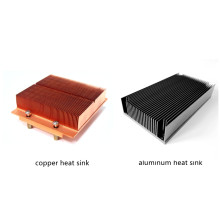

Aluminum alloys are common heat sink material because they are cheaper than copper.

However, if you need higher levels of thermal conductivity, copper is the best option.time2021/06/13

-

Many heat sink designs require machining in order to make sure that they deal with the heat management challenge that they were designed to address.

time2021/06/16

-

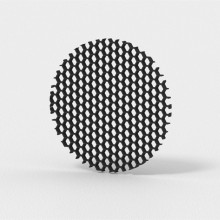

The most common use of the hex louver is the reduction of the glare of the light source and luminaire.

time2021/06/18

-

Jeasnn custom-manufactures precision shafts and pins to your specifications, with length and diameter tolerances depending upon the size and end configuration.

time2021/06/23

-

Aluminum offers excellent machinability, durability, low weight, and low cost for a variety of parts in a variety of industries.

time2021/07/17

-

Metal lighting accessories play a crucial role in outdoor environments, where they must withstand harsh weather conditions while maintaining their functionality and aesthetic appeal.

In this guide, we delve into two primary surface treatment methods anodizing and powder coating and their significance in enhancing the durability and visual allure of outdoor lighting fixtures.time2024/03/18

-

Design and Planning: This stage involves conceptualizing the landscape lighting system and its components. Designers consider factors like the type of lighting needed (ambient, accent, or task lighting), the layout of the landscape, energy efficiency requirements, and aesthetic considerations.

time2024/05/24

-

Chinese manufacturers are setting new benchmarks in the lighting industry with their expertise in custom CNC machined brass downlight housings. Renowned for precision and quality, these manufacturers leverage cutting-edge technology and skilled craftsmanship to deliver high-performance and aesthetically pleasing lighting solutions.

time2024/06/28

-

Chinese manufacturers are setting new benchmarks in the lighting industry with their expertise in custom CNC machined brass downlight housings. Renowned for precision and quality, these manufacturers leverage cutting-edge technology and skilled craftsmanship to deliver high-performance and aesthetically pleasing lighting solutions.

time2024/07/30

-

As the lighting industry continues to push the boundaries of design and functionality, CNC (Computer Numerical Control) machining has emerged as a pivotal technology in the production of aluminum parts for downlights. This cutting-edge process is transforming the way lighting components are manufactured, offering unparalleled precision and customization.

time2024/08/28